Realize your "New Technology" with our Dies and Jigs

Have you ever experienced a situation where you are forced to change dies because you don't have enough press machines due to an increase in the number of processes?

Some customers may find it difficult to pay for the additional purchase of a press machine

or find space to install it.

If only there was a compact trim pierce dies that could be processed without a press machine...

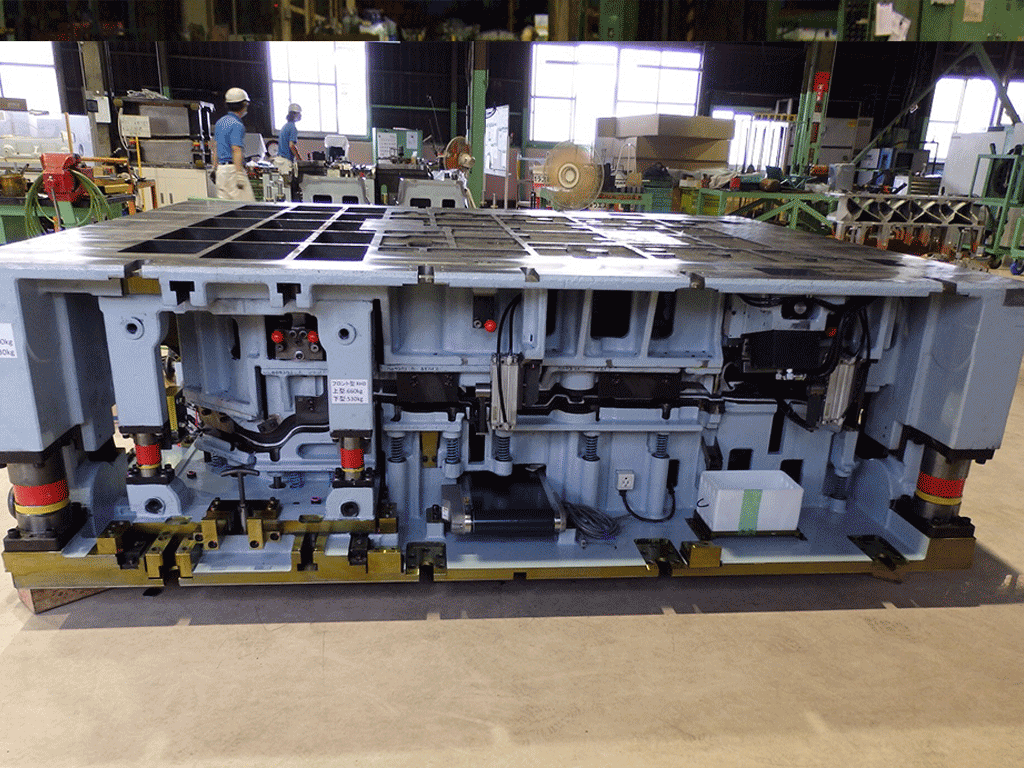

If you can complete the processes required for the two or three dies with a single die...

We'll solve that trouble!

As a manufacturer specializing in dies, we provide design proposals and advice and help you make products efficiently and better. We will also propose the most appropriate measures for the realization of development projects, such as prototypes of new products.

Our strengths

REASON

01

High quality and

timely delivery

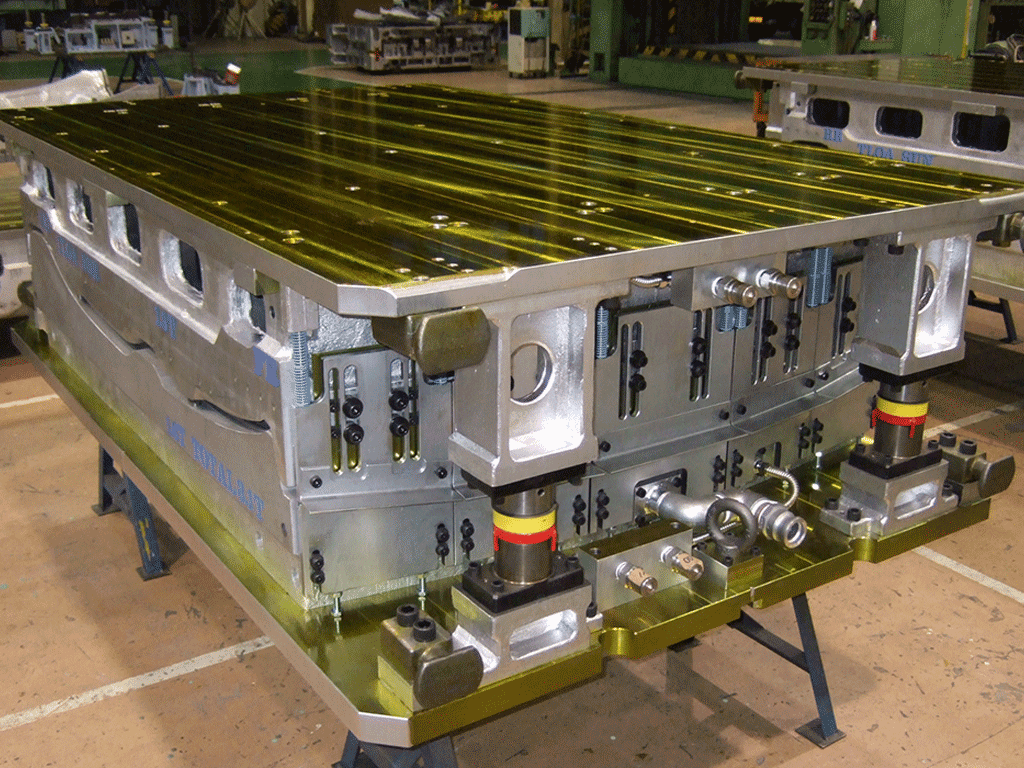

The 3D CAD and die design supported by the analysis software minimize the maintenance effort and enable the production of high-quality dies with excellent durability and abrasion resistance in a short time.

REASON

02

Craftsmanship

The trim pierce type, which many customers have trouble with, provides a sharpness that will definitely satisfy your needs. Even if your request requires highly difficult technology, we will help you realize it with an uncompromising attitude.

REASON

03

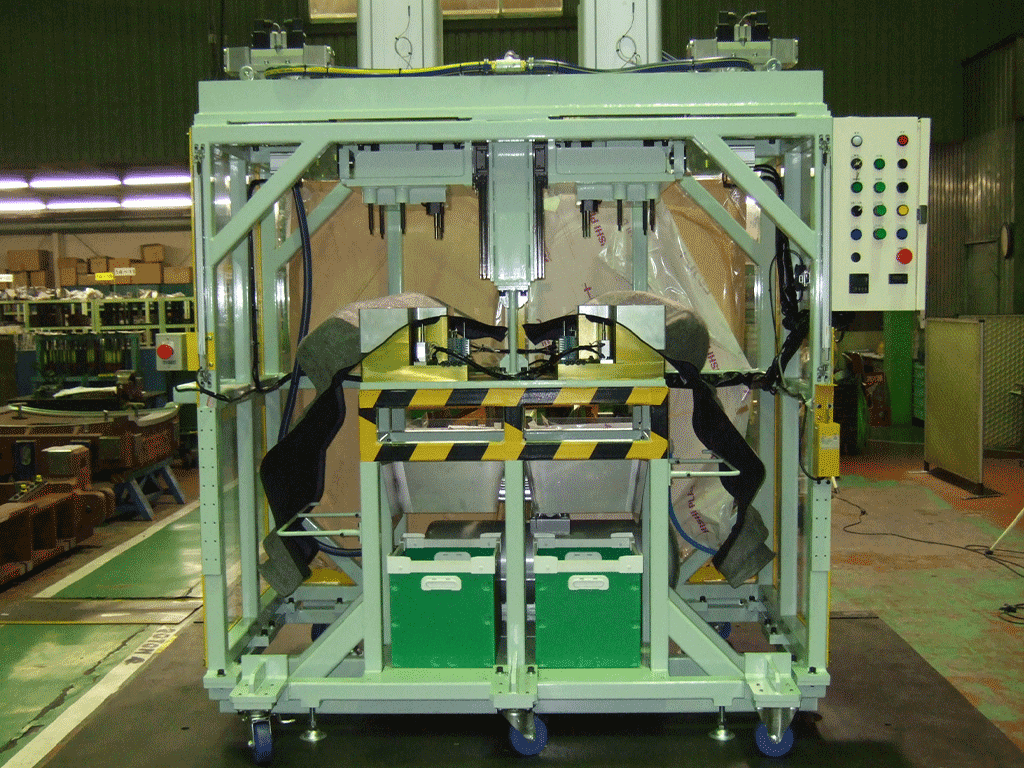

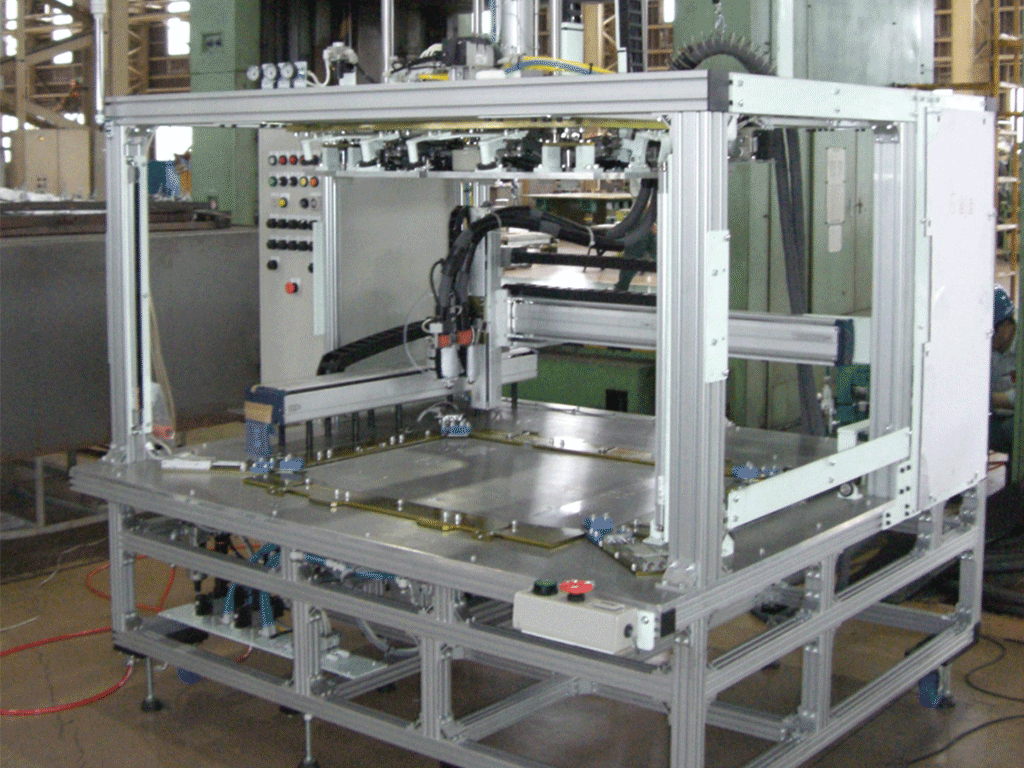

Facilities

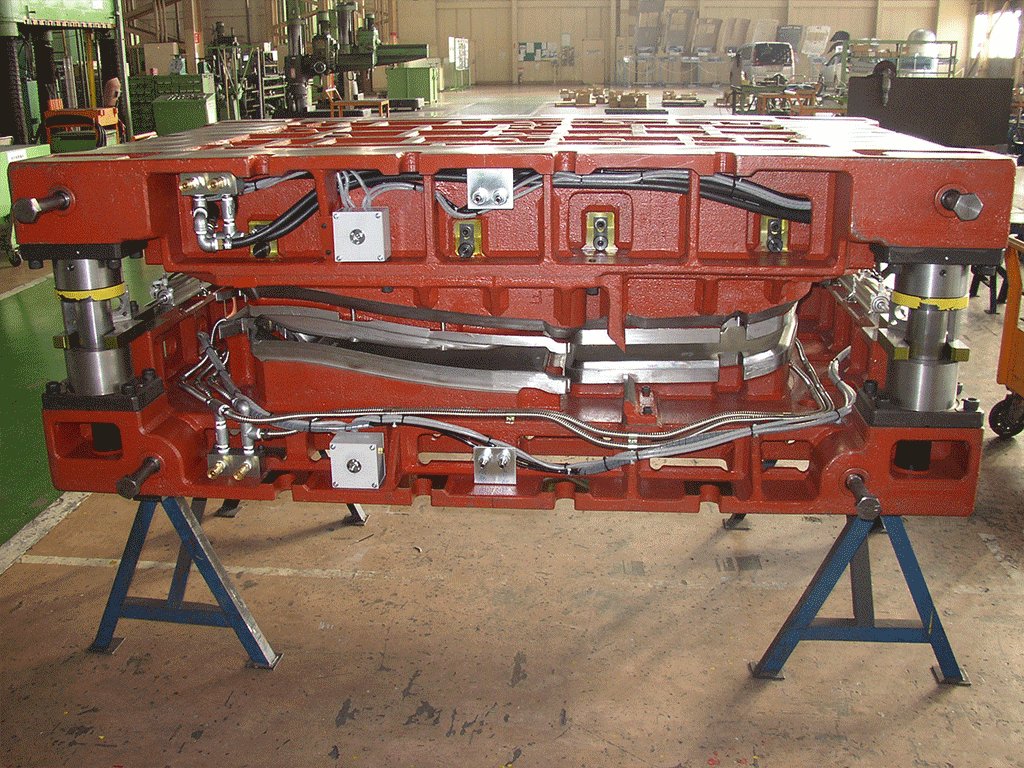

Compatible with pneumatic, hydraulic, cooling, temperature increasing, and electric control. It is possible to try using a heating furnace or die temperature controller.

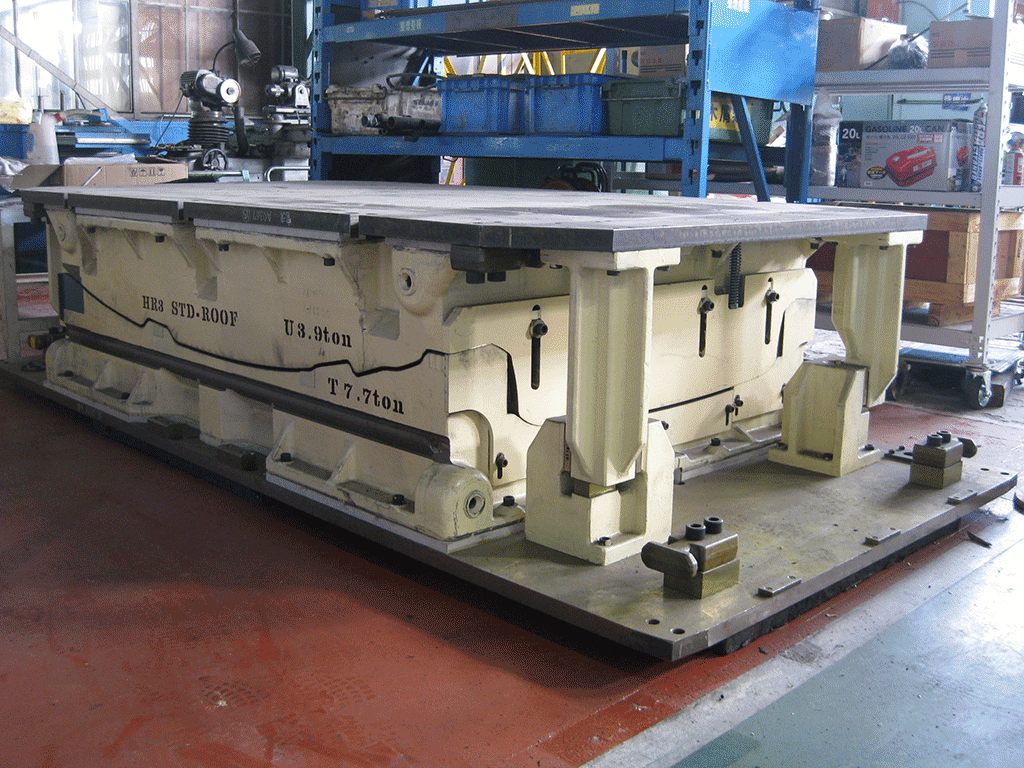

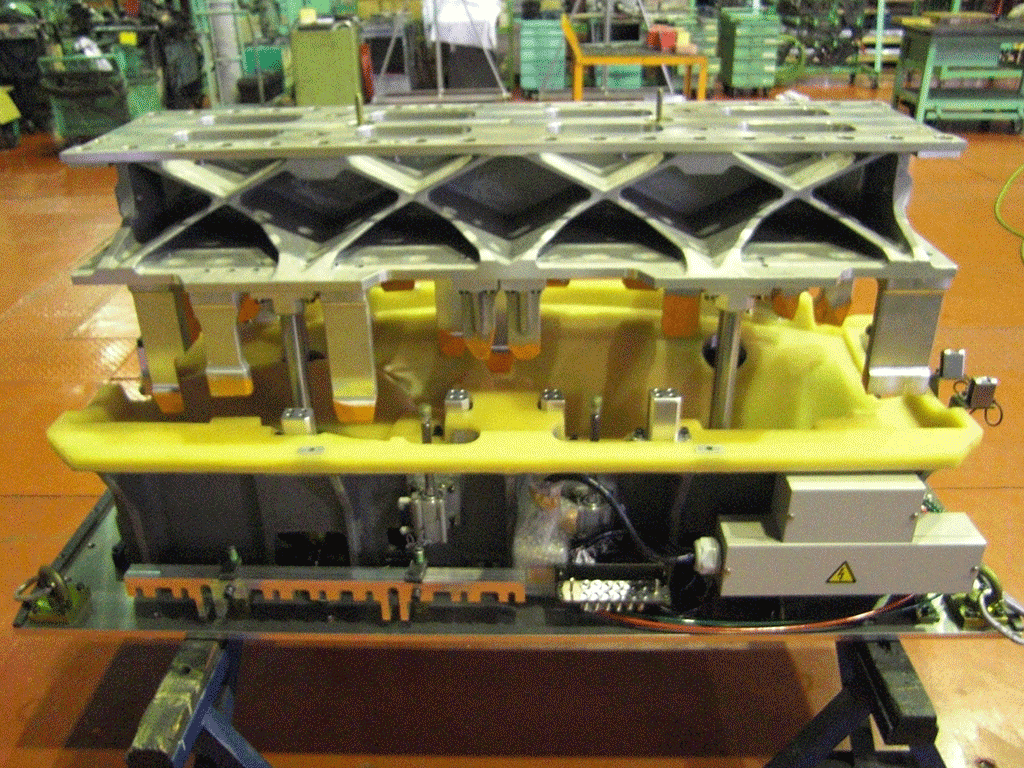

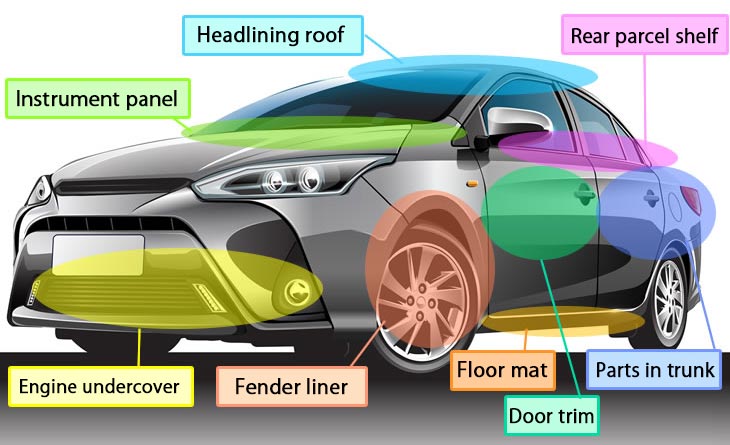

Interior parts - Example

Example of our experience

We will resolve

your company's concerns and problems!

Since the company's press and other equipment are insufficient, the die must be replaced if the number of processes increases...

We propose the most suitable tools, such as dies and jigs that do not require a press, that combine multiple processes in accordance with your request!

Dies made by other companies, but many cutters are missing or defective...

Repair, adjustment, and maintenance of dies made by other manufacturers are also possible!

As a specialized manufacturer of high-quality dies, we will use our know-how and technical capabilities to help speed up the recovery process!

The fabric and other fibrous material cannot be cut cleanly....

We realize a high-quality and beautiful finishing by changing the die material depending on the product material.

Difficulty in die maintenance...

Our dies are extremely durable and wear resistant and are almost maintenance-free.

It is difficult to make specifications due to lack of knowledge of dies and jigs...

From the product design stage, we will support the investigation of optimal line processes!

We will reduce your trouble as much as possible and deliver the best products for good manufacturing.

Contact

Please feel free to contact us for job inquiries and estimates.